Liquid continuous sterilizer

- Applicable to a wide variety of liquids sterilization such as beverages, milk, seasonings and alcohols.

Selecting the optimal method from plate, tube, spin-injection, and joule for heat transfer elements in order to improve yields and quality, and stable operation.

- Plate heat exchanger for food(FX series)

- Food dedicated plate to solve the problem of food production line

See more

- Plate heat exchanger for food(FX series)

- Food dedicated plate to solve the problem of food production line

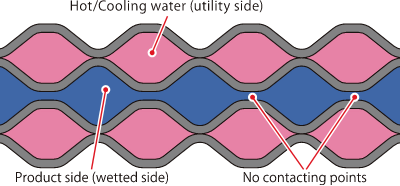

Smooth and product-friendly liquid flow through the plate provides uniform heating and quick liquid replacement characteristics.

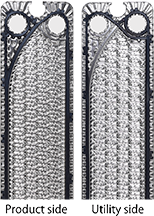

The electrolytic polishing plate prevents from the scales and burnt, and can be cleaned with CIP.

Features

- Uniform and smooth liquid flow realizes uniform heating and cooling of products, reducing the amount of holding liquid.

- The electrolytic polishing plate reduces the deposition of the scale, allowing long continuous operation.

- Improved cleanability by greatly reducing the number of contact points between plates and preventing from the scales and burnt.

- By realizing the piston flow, the liquid replacement time is greatly shortened, and it contributes to the reductions of the operation time and products loss.

Liquid displacement test data

Introducing the test cases of the liquid sterilizers

Applications

| Beverages | Bottled water, water, tea, juice, coffee, soda (syrup), milk, cream, condensed milk, jelly, yogurt, mayonnaise, etc. |

|---|---|

| Brewings | Soy sauce, noodle soup, sake, cloudy sake, amazake, liqueur, wine, whisky, shochu, etc. |

Scope of the application

FX series lineup

Note: Please be aware that the dimensions may be changed without notice.

Applicable Material

Plate / SUS316, Titanium

Gasket / EPDM, fluorine resin cushion gasket (TCG), silicon

Plates for solids

Plates for solids

Features

- The heat-transfer area where liquid flows on the product side has no contact points where the plates come into contact with each other, so pulp is less likely to get caught.

- Food-specific plate: Inherits the good liquid displacement and washability of the FX-03 type

Structural drawing (cross-sectional view)

Plate shape

- The plate inherits the vertical structure and gentle shoulder shape of conventional products.

Features

- It reduces accumulation of solids at hit points (vegetable drinks, tomato juice, ketchup, etc.)

- It reduces the effects of shearing (cream, liquid egg, etc.)

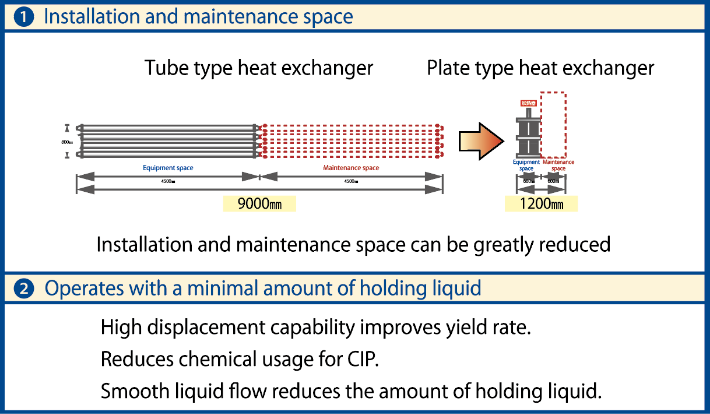

- Plate type sterilizer(RMS : Liquid continuous sterilizer)

- Preparation, sterilization, extraction and reaction of the food

See more

- Plate type sterilizer(RMS : Liquid continuous sterilizer)

- Preparation, sterilization, extraction and reaction of the food

The positive pressure operation is performed to increase the pressure on the sterilizing liquid side, and the safety measure against plate cracking is possible.

Features

- Stainless steel, super stainless steel and titanium, etc. are available for the plate material.

- Plate for food use improves yield and allows for long-term operation.

- The use of fluorine resin cushion gasket reduces foreign matter contamination, residual fragrance, and the frequency of gasket replacement.

Applications

| Beverages | Bottled water, water, tea, juice, coffee, soda (syrup), milk, cream, condensed milk, jelly, yogurt, mayonnaise, etc. |

|---|---|

| Brewings | Soy sauce, noodle soup, sake, cloudy sake, amazake, liqueur, wine, whisky, shochu, etc. |

- Tube type sterilizer(RMS : Liquid continuous sterilizer)

- Multi-product production with a wide range of lineup

See more

- Tube type sterilizer(RMS : Liquid continuous sterilizer)

- Multi-product production with a wide range of lineup

Sterilizers corresponding to the multi-product production for water soluble liquid, high viscosity liquid, solids or fiber containing liquid, etc.

Depending on the conditions such as liquid properties and processing amount, they are supported by a rich lineup of single tube, multi tube, shell & tube, and triple tube.

Features

- Many types of liquid are applicable, and it can be applied to products from low to high viscosity (~10,000 mPa・S), containing solids and fibers.

- Excellent liquid replacement is best for a wide variety of products.

- Easy maintenance due to limited use of gaskets.

- The small wetted area of the gasket reduces the flavoring and residual fragrance.

- Uniform flow realizes excellent detergency, allowing for long-term operation even for products that are easy to burnt.

- Double tube type

- Multi tube type

- Triple tube type

Applications

| Seasonings | Barbecue sauce, dressings, mayonnaise, sauces, ketchup, mash vinegar, amino acids, sesame sauce, miso sauce, noodle soup, pot soup |

|---|---|

| Beverages | Fruit juice, juice, soy milk, juice, tea, sports drink, coffee, amazake |

| Milks | Milk, coffee milk, cream, pudding, jelly |

| Extracts | Meat extract, seafood extract, vegetable extract, soup |

| Others | Health drink and health food |

- Spin-injection type sterilizer(RMS : Liquid continuous sterilizer)

- Direct steam heating system provides high uniformity and efficient heating

See more

- Spin-injection type sterilizer(RMS : Liquid continuous sterilizer)

- Direct steam heating system provides high uniformity and efficient heating

It is a sterilizer of the direct steam heating system type developed independently.

The system improves the problem of a conventional direct heating system, and it is effective in the liquid that gets the scale easily.

Features

- Instant supply of direct steam while stirring to achieve high uniformity and efficient heating.

- High quality continuous operation without burning or over-heating.

- Self-pressurization enables operation with low-pressure steam.

- The flow rate and pressure can be numerically controlled by controlling the rotation speed facilitating a wide variety of processing.

- Simple structure with excellent cleaning and high maintainability.

Applications

Dessert, soy milk, blue juice, cream, collagen, gelatin, fruit juice, tea beverage, vegetable juice, liquid diet, sesame sauce, raw milk, cheese, etc.

*By flash cooling, it is effective for the flavor improvement.

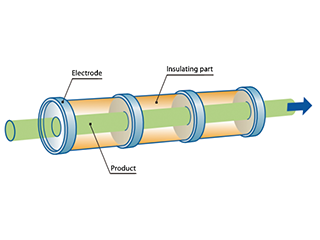

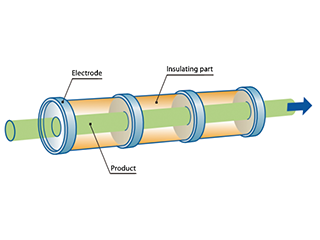

- Joule type sterilizer

- Jams, etc., are heated for a short time by electric current

See more

- Joule type sterilizer

- Jams, etc., are heated for a short time by electric current

Short-time heat treatment by electric current, such as fruit prep.

Features

- A system that conducts electricity through the food material and heats it by self-heating due to its electrical resistance.

- Ideal for high-viscosity liquids that are difficult to heat with conventional heating, and for liquids and solids that need to be heated in a short time.

- Hybrid system is possible: indirect heating for low-temperature parts and Joule heating only for high-temperature parts where quality is easily damaged.

Applications

- Fruits : fruit preparations, jams

- Paste : ginger, garlic, bean paste

- With solids : dressings, sauces, etc.

- Liquid continuous sterilization testing machine

(UHT testing machine)

- Proposals by purpose from a wide variety of product lineup

See more

- Liquid continuous sterilization testing machine

(UHT testing machine) - Proposals by purpose from a wide variety of product lineup

Plate type UHT tester

Scalability evaluation and other tests that take compatibility with production machines into consideration are possible.

- Processing volume : 40-60L/H

- Temperature conditions : sterilization 95-140℃, cooling 85℃/30℃

Tube type UHT tester

Minimizes liquid loss and suppresses fragrance deposition.

- Processing volume : 40-60L/H

- Temperature conditions : sterilization 95-140℃, cooling 85℃/30℃

Ultra-low volume plate type UH tester : STS-100

A simple UHT test can be easily performed with a very small amount of sample solution.

- Processing volume : 5L/H

- Temperature conditions : sterilization 95-140℃, cooling 30℃ (manual operation)

Direct steam-heated UHT tester

Newly developed Spinjection can be tested.

- Processing volume : 30-60L/H

- Temperature conditions : sterilization 95-155℃, flash cooling 85-60℃

- Since an injection is included, comparison tests with spin-injection are possible.