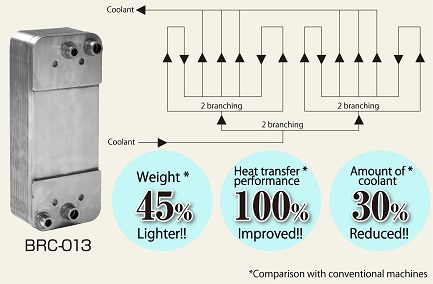

Resource saving

Plate heat exchanger BRC-013 greatly improves the problem of uneven distribution of coolant in plate type evaporators used in refrigeration and air conditioners, realizes miniaturization through improved performance, and contributes to the prevention of global warming by conserving resources and reducing the amount of fluorocarbon charged. In 2018, this product received the Parts Award in the Environment, Resources, and Energy Sectors at the "Super Manufacturing Parts Award".

CO2 Recovery

Reducing CO2 emissions in order to prevent global warming is a common issue for the entire world.

In order to respond to this issue, HISAKA WORKS developed the plate heat exchanger SX-80 series for CO2 recovery plants using the chemical absorption method. Specialized for heat recovery in heating and cooling process for amine solution, a CO2 absorbent, this new product achieves highest-level heat recovery and long-term stable sealing. HISAKA WORKS heat exchangers will continue to contribute to the realization of a low-carbon society.

Energy Saving

HISAKA WORKS has made various energy-saving proposals using plate heat exchangers to various plants, helping to improve the profitability of our customers' plants. Based on our numerous successes, we have also prepared a catalog introducing energy-saving applications using plate heat exchangers and energy-saving cases that combine them. HISAKA WORKS will continue to help promote energy-saving for our customers.

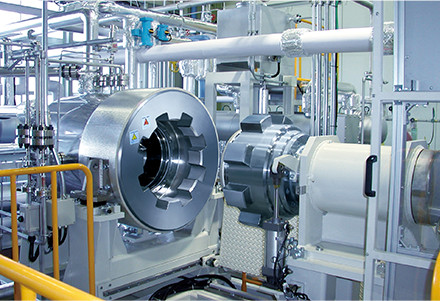

Decarbonation

As carbon neutrality is promoted, demand is increasing for the products that save energy and emit less CO2. HISAKA's concentrator with MVR (self vapor compressor) enables reuse of vapor by compressing vapor evaporated in the concentrator with a vapor compressor. We will continue to actively develop new products that contribute to the reduction of environmental burdens such as CO2 emissions, crude oil volume, and costs.

Energy Saving & Water Saving

The Circular, an environmentally friendly jet dyeing machine that does not use excess water, has achieved a reduction in the liquid ratio by adopting a new structure that includes a dyeing tank and a compact heat exchanger. In addition to energy and resource savings, it also contributes to improved productivity and quality, and stabilized processing quality. Together with high functionality options, it contributes to further energy saving and productivity improvement in dyeing factories. and productivity in dyeing factories.

Water Saving

In the dyeing process for fabric products, which use large amounts of water, it is necessary to perform drainage treatment to prevent water pollution. In order to solve this problem, HISAKA WORKS is engaged in developing a visionary supercritical dyeing machine that does not create drainage water, is environmentally friendly, and uses supercritical CO2 gas. We expect that this technology will be applied not only to dyeing but also to special processing such as cleaning and functionalization. We will continue to develop new technology to contribute to reducing the burden on the global environment.

Valves

Regarding industrial ball valves which primarily use stainless steel, we have many successes in environmental-related industries, including not only chemicals, which is the main market, but also iron and steel, food, electric power, industrial waste (sludge, waste oil, waste fluid, waste plastic, etc.) and general waste treatment plants, and many of our products are used under harsh conditions such as powders, slurry, and high-temperature applications. We will continue to provide products and services that meet our customers' needs, contributing to fluid control for efficient plant operation.

Pharmaceuticals

Our sterilizers, born through use of sterilization technology for food, are used in the sterilization of pharmaceuticals and medical equipment.

In particular, many of the IV transfusions used in Japan are produced using sterilizers from HISAKA WORKS. By supplying highly-reliable pharmaceutical equipment, from the concentration, sterilization, and drying of Chinese herbal medicines and crude drugs to cutting-edge bio-pharmaceutical manufacturing equipment, we will continue to contribute to pharmaceutical manufacturing with safety and ease of mind.

Food

As interest in "safety and ease of mind for food" continues to increase, HISAKA WORKS has provided cutting-edge food sterilizers for pouch foods and various other food products to numerous food manufacturers. Approximately 70% of the pouch food products you see in stores use sterilizers from HISAKA WORKS. By enabling long-term storage at room temperature through pouch sterilization that does not use preservatives or disinfectant, pouch foods ensure safety and ease of mind with virtually no change in quality. This makes them fit not only for general home consumption, but also for stockpile / emergency foods in case of a disaster or emergency.

Looking ahead to its 100th anniversary in 2042, HISAKA established its New Business Promotion Department in 2018 in order to explore and promote commercialization of new operations and new products which consolidate fluid heat and pressure control technology to solve social issues involving energy, water, and food.